Hospitality Design Philosophy

For over two decades, ModernRugs.com has been the leading resource among trade professionals, receiving custom commissions for all types of residential, commercial and hospitality projects. With a portfolio highlighting various projects including dynamic workplaces, shopping malls, renowned restaurants and internationally acclaimed resort hotels, our work is a testament to our expertise and craftsmanship.

We love when our clients share the same enthusiasm that we do when it comes to the design process behind creating your unique rug. From drafting the design and coordinating colors to deciding on appropriate materials and constructions, our design team will encourage your involvement and outfit you with all the knowledge you need to call the shots. With us, you have the ability to choose the size, shape, design, construction, materials and colors to create your one-of-a-kind rug.

Of course, this option isn’t for everyone so, rest assured, our talented team will expertly handle the entire process for you to make sure that your rug turns out exactly how you intended, with no surprises. We understand that starting from scratch can seem overwhelming, so if you have a motif in mind but are lacking the inspiration, we suggest choosing from our library of thousands of preexisting designs that can be customized to meet your exact aesthetic needs.

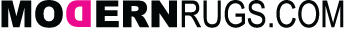

Each custom rug is a true work of art because it is made with the finest materials nature offers and the unique touch of the human hand.

We source our own raw materials so that we can dye them and hand spin them ourselves. This environmentally sustainable focus helps generate local employment opportunities within our cherished weaving communities while also eliminating unnecessary chemical waste and machine pollution.

Our Manufacturing Countries

The most prominent manufacturing countries are the United States, India, China, Egypt and Turkey. Like any other industry, each country has its comparative advantages. India, and China for example, are the world’s leader in hand-tufted rugs because of their skilled labor. The United States, Egypt and Turkey, and on the other hand, have the proper infrastructure and knowledge to create a large volume of machine made rugs.

United States

Today, carpet mills located within a 65-mile radius of Dalton, Georgia, produce about 85% of the carpet sold in the U.S. market. The U.S. industry accounts for about 45% of the world’s carpet production.

India

India is well known for manufacturing hand knotted and hand tufted rugs. The most common fiber used in India is wool, although it’s not unusual to find rugs made of synthetic fibers like polyester or viscose.

China

China is one of the largest manufacturers of hand tufted rugs and hooked rugs, including shags. The most commonly used fibers in China are synthetics, like polyester and polypropylene. China is a manufacturer of indoor/outdoor rugs, constructed of synthetic fibers that are engineered to resist damage from water and UV.

Egypt

Egypt is the world’s largest manufacturer of machine made rugs. Rugs from Egypt are power loomed on a Wilton loom, which uses a mechanism to regulate the feeding of pile yarns into the loom to form a pattern. Machine made rugs can be made using nearly any fibers, although synthetic fibers are most commonly used.

Turkey

Like Egypt, Turkey manufactures a significant volume of the world’s machine made rugs. The rugs are power loomed using essentially the same machines that are used in Egypt.

Fiber varieties.

Picking the ‘right’ fiber is contextual. You have to consider things like cleanability, durability, softness, shedding, color retention, and more. In fact, sometimes synthetic fibers like polypropylene or polyester are better choices than natural fibers because they’re stain resistant, fade resistant, and soft. Understanding the ten fibers on the following page will help you determine what meets your project requirements.

WOOL

The most commonly used natural fiber in rug production. Wool usually refers to fibers from sheep. Fiber diameter is the single most important characteristic determining price and quality.

SILK

Silk is an extremely fine lustrous fiber. It can be used to weave rugs with extremely high knot counts adding shine, shimmer, and sparkleto highlight certain aspects of designs.

NYLON

Nylon is most noted for its durability. Because it’s the hardest of all the synthetic carpet fibers, it resists wear and abrasion. A nylon carpet will usually last longer than one made from another type of fiber.

VISCOSE

Synthetic, shiny fiber—sometimes called ‘art silk’. Oftentimes used as a more affordable substitute for silk. Some rugs are made of 100% viscose, but it’s more commonly used as an accent fiber.

POLYESTER

Very affordable. Wears well and feels very soft, especially when used for rugs with a thick pile. Moisture, stain and abrasion-resistant.Retains color well over time and is easy to clean.

JUTE

A naturally shiny vegetable. Relatively affordable and second only to wool as the most produced natural fiber for rugs.

POLYPROPYLENE

Very affordable. Easy to maintain and highly durable. Bold, fade-resistant color. Commonly used in indoor/outdoor rugs for its UV, mildew and stain-resistant qualities.

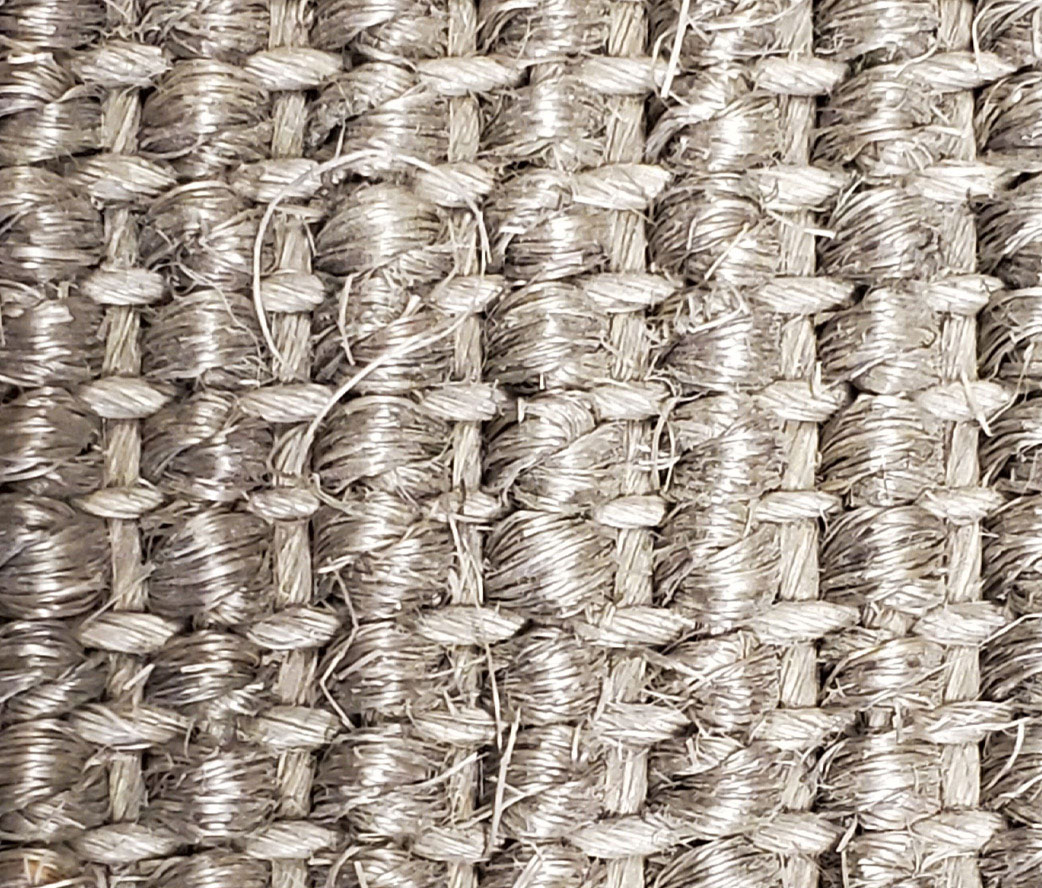

SISAL

A natural fiber that stems from the agave plant. Attracts minimal dust to rug and is static free. Highly sustainable.

COTTON

Natural and soft. Sometimes used as thread for the base of a rug. Easy to clean and maintain.

TENCEL

Tencel is 99% decomposed wool pulp from tree farms. Along with being a great sustainable material, it is a breathable fiber which is 50% more resistant to mold than cotton or wool.

Hospitality Rug Applications

At ModernRugs.com we work to make your commercial space beautiful by providing luxurious, custom rugs of superb commercial quality. We have been at the forefront of commercial and hospitality f loor coverings for over two decades, providing extraordinary quality handmade rugs for every space.

Our commercial hospitality area rugs contribute to a wealth of design sectors including retail spaces, workplaces and hospitality enviroments. Product durability and design flexibility make our rugs a perfect fit for any project you may have. Our commercial collection was developed for the most demanding hospitality environments.

The following pages will help you understand more about our main rug construction types, including their respective durability, defining characteristics, and how they are made.

TYPES OF CONSTRUCTION

The Five Most Common.

| Construction | Price Point | Manufacturing | Durability |

|---|---|---|---|

| HAND KNOTTED | 10-12 weeks | 20+ years | |

| HAND TUFTED | 6-8 weeks | 7-10 years | |

| QUICKSHIP | 2-4 weeks | 7-10 years | |

| MACHINE MADE | 8 weeks | 7-10 years | |

| FLAT WEAVE | 3-4 weeks | 7-10 years |

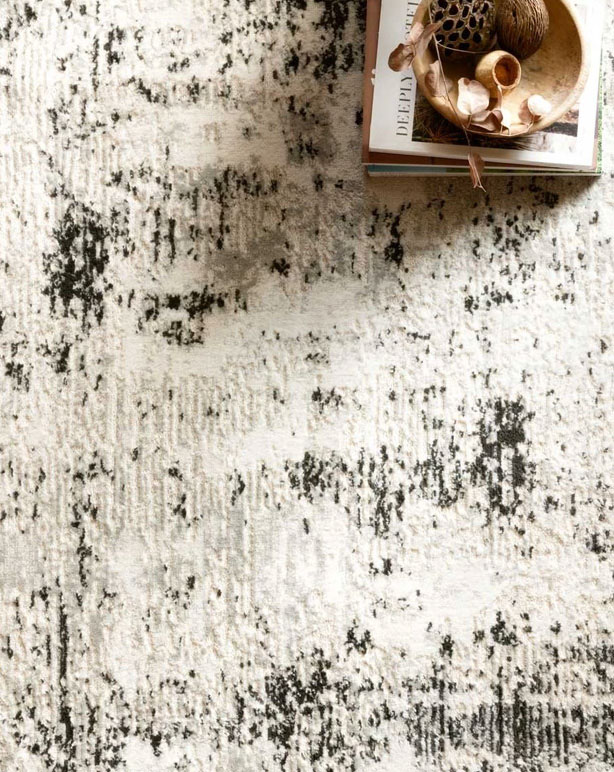

Hand Tufted Rugs

Hand tufted rugs are a great example of how technological advancements have made luxury more accessible. Because hand tufted rugs are created with the help of a mechanized hand tool, the process is much quicker and less labor intensive than hand knotting. Therefore, the lead time is shortened and the price is more affordable than a hand knotted rug. A hand tufted rug can always be distinguished from a hand knotted rug because of the cloth backing glued to the underside.

| ORIGIN | India, China, Thailand |

|---|---|

| PRODUCTION TIME | 6-8 weeks EXPEDITED 5 weeks |

| SIZE LIMITATION | None |

| COLOR LIMITATION | PantoneTM, Sherwin Williams, ARS 600, ARS 1200, ARS 1600, Custom dye to match. |

| SHAPE LIMITATION | None |

| MINIMUM QUANTITY | None |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| PILE HEIGHT | 0.625 in |

| BACKING | Canvas |

| MATERIALS | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk., metallic thread, fiber optics, |

| DYE OPTIONS | Solid, abrash, double dye, salt and pepper. |

| FINISHING OPTIONS | Cut pile, cut and loop, high-low, carving, oddshape, ADA Compliance |

| APPLICATIONS | Lobbies, hotel rooms, presidential suites, high end residential. and boutique hotels, boardrooms. |

Hand Knotted Rugs

Hand knotted rugs reflect the oldest and most traditional process of rug-making. Created with tremendous patience and pride, these magnificent and functional rugs are an investment that actually appreciates in value because of how beautifully they age. These rugs are created by tying knots of wool yarn onto a loom - a simple yet incredibly tedious process. The more knots per square inch, the higher the quality and price. Density ranges anywhere from 25-1000 knots per square inch. So, to give you an idea of how laborious construction is - it takes a skilled weaver about 10 seconds to tie each knot, meaning a 9’x12’ rug, using 150 knots per square inch, would take 6,480 hours to complete. However, knotted rugs are usually woven by two or three to reduce the lead time. We offer the following hand knotted qualities: : 80 knots per inch and 5/8” pile height 100 knots per inchand 3/8” pile height 110 knots per inch and 3/16” pile height

| ORIGIN | India, Nepal, China, Turkey |

|---|---|

| PRODUCTION TIME | 12-14 weeks EXPEDITED 10 weeks |

| SIZE LIMITATION | None |

| COLOR LIMITATION | PantoneTM, Sherwin Williams, ARS 600, ARS 1200, ARS 1600, Custom dye to match. |

| SHAPE LIMITATION | None |

| MINIMUM QUANTITY | None |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| DENSITY | 40-300 Knots Per Square Inch |

| BACKING | None |

| MATERIALS | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics, |

| DYE OPTIONS | Solid, abrash, double dye, salt and pepper |

| FINISHING OPTIONS | Cut pile, cut and loop, high-low, carving, oddshape, ADA Compliance |

| APPLICATIONS | Lobbies, hotel rooms, presidential suites, high end residential. and boutique hotels, boardrooms. |

Hand Loomed Rugs

Contemporary hand-loomed rugs originate from an ancient weaving process and are still woven in a similar manner today. Hand-loomed rugs are woven by hand with the aid of a mechanical loom on a grid-like “foundation” of cotton fibers. This “foundation” of cotton fibers serves as the skeleton of the rug, with the fibers woven around the “foundation” vs. hand-tied like in a hand-knotted rug. Hand-loomed rugs are less labor intensive than other forms of rugs, which makes them cost-effective for low-traffic situations. However, hand-loomed rugs are not recommended for commercial use due to strength of the construction.

| ORIGIN | India |

|---|---|

| PRODUCTION TIME | 4-6 weeks EXPEDITED 3-4 weeks |

| SIZE LIMITATION | 15’ ft width |

| COLOR LIMITATION | PantoneTM, Sherwin Williams, ARS 600, ARS 1200, ARS 1600, Custom dye to match. |

| SHAPE LIMITATION | solid color and horizontal stripes, rectangular shapes |

| MINIMUM QUANTITY | None |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| PILE HEIGHT | 0.25 in |

| BACKING | None |

| MATERIALS | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics, polyester and polypropylene |

| DYE OPTIONS | Solid, salt and pepper. |

| FINISHING OPTIONS | ADA Compliant, cut pile, cut/loop pile optional |

| APPLICATIONS | Outdoor, Lobbies, hotel rooms, residential, presidential suites, hallways, yachts, wall-to-wall. |

Power Loomed Rugs

Power loomed rugs use the same construction method as hand-loomed rugs, but they are done via machine without any human touch. A computer dictates texture, design, and color, allowing for a remarkably consistent product. Unlike all other constructions, power loomed rugs have distinctive production restrictions. In a power loomed collection, rugs are restricted to a particular set of colors once in production. Large machines have hundreds of spindles of fiber that are mechanically woven into a thin mesh backing. The machine is computer driven and runs continuously to maximize efficiency. The backside of a rug is the easiest way to distinguish its construction. Like hand knotted rugs, you can see the design/colors on the back of a machine made rug, but it has a coarse latex backing that secures it in place

| ORIGIN | India |

|---|---|

| PRODUCTION TIME | 5-6 weeks EXPEDITED 4-5 weeks |

| SIZE LIMITATION | 15’ ft width |

| COLOR LIMITATION | PantoneTM, Sherwin Williams, ARS 600, ARS 1200, ARS 1600, Custom dye to match. |

| SHAPE LIMITATION | solid color and horizontal stripes, rectangular shapes |

| MINIMUM QUANTITY | None |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| PILE HEIGHT | 0.25 in |

| BACKING | None |

| MATERIALS | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics, polyester and polypropylene |

| DYE OPTIONS | Solid, salt and pepper. |

| FINISHING OPTIONS | ADA Compliant, cut pile, cut/loop pile optional |

| APPLICATIONS | Outdoor, Lobbies, hotel rooms, residential, presidential suites, hallways, yachts, wall-to-wall |

QuickshipTM Dye Injected Rugs

The Quick Ship collection brings creativity to life in precise lines, photo realistic detail, vivid color and smooth gradients - all translated in 76 dpi high-definition, dye injection technology delivering five times the clarity of existing carpet color processing machines. Quick Ship offers high-speed production without compromising color, detail, precision and performance.

| ORIGIN | USA or CHINA |

|---|---|

| PRODUCTION TIME | 4 weeks |

| SIZE LIMITATION | 12' Width |

| MINIMUM QUANTITY | 250 yards - ( order may have multiple designs if totaling 250 yards ) |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| PILE HEIGHT | 0.25 in |

| BACKING | Woven Polypropylene |

| PILE MATERIAL | Nylon |

| DYE OPTIONS | Injected |

| FINISHING OPTIONS | Cut Pile, Textured |

| APPLICATIONS | Lobbies, Guest Rooms, Residential, Suites, Workplaces, Public Areas, Hallways, Yachts, Airplanes, Wall-to-Wall |

Machine Made Rugs

Machine-made rugs can be made out of common materials like wool or silk but can also be created with synthetic materials like polypropylene, nylon, polyester, and acrylic. Depending on personal preference, these types of materials could work well in your environment or clash with the overall theme. Although these materials are synthetic, some of them have the ability to hold up extremely well.

| ORIGIN | China, Turkey, Portugal |

|---|---|

| PRODUCTION TIME | 4-12 weeks EXPEDITED 10 weeks |

| SIZE LIMITATION | 15’ ft width |

| COLOR LIMITATION | Eight |

| SHAPE LIMITATION | None |

| MINIMUM QUANTITY | 1000 yards |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| PILE HEIGHT | 0.25 in |

| BACKING | None |

| MATERIALS | Matte nylon, luster nylon, Polyester and Polypropylene |

| DYE OPTIONS | Injection dye, solution dye |

| FINISHING OPTIONS | ADA Compliant, cut pile, cut/loop pile optional |

| APPLICATIONS | Lobbies, hotel rooms, residential, presidential suites, hallways, yachts, wall-to-wall. |

Flat Weave Rugs

Usually the most affordable rug construction, flatweave rugs are also a popular and dynamic option. While many are made for outdoor application, flatweaves are also increasingly popular in interiors, either as an accent rug, layered underneath other rugs, or in no-frills areas. Common fibers in flatweave rugs include synthetic yarns like polyester, polypropylene, and nylon. Wool and natural fibers are also popular choices for flatweave rugs. Flat woven rugs are typically woven by hand with tight, compact piles and simple patterns. The method by which flatweave rugs are created typically only allows for patterns composed of straight lines. Flat weave rugs are known for their resilience - hence why it is a popular construction for functional and outdoor applications.

| ORIGIN | India |

|---|---|

| PRODUCTION TIME | 6-8 weeks EXPEDITED 4 weeks |

| SIZE LIMITATION | None |

| COLOR LIMITATION | PantoneTM, Sherwin Williams, ARS 600, ARS 1200, ARS 1600, Custom dye to match. |

| SHAPE LIMITATION | None |

| MINIMUM QUANTITY | None |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| PILE HEIGHT | 0.25 in |

| BACKING | Optional canvas |

| MATERIALS | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics, polyester and polypropylene |

| DYE OPTIONS | Depending on Material |

| FINISHING OPTIONS | ADA Compliant |

| APPLICATIONS | Outdoor, Lobbies, hotel rooms, residential, presidential suites, hallways, yachts, wall-to-wall. |

Summary

| CONSTRUCTION | LEAD TIME* | SIZING | AVAILABLE MATERIALS | AVAILABLE FINISHING |

|---|---|---|---|---|

| Hand Tufted | 6-8 weeks | Min Length: any Min Width: any Max Length: any Max Width: any | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics. | Cut pile, cut and loop, high-low, carving, odd-shape, ADA Compliance |

| Hand Knotted | 12-14 weeks | Min Length: any Min Width: any Max Length: any Max Width: any | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics. | Cut pile, cut and loop, high-low, carving, odd-shape, ADA Compliance |

| Hand Loomed | 4-6 weeks | Min Length: any Min Width: any Max Length: any Max Width: 15 ft | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics,polyester and polypropylene | ADA Compliant, cut pile, cut/loop pile optional |

| Power Loomed | 5-6 weeks | Min Length: any Min Width: any Max Length: any Max Width: 15 ft | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics,polyester and polypropylene | ADA Compliant, cut pile, cut/loop pile optional |

| Quickship | 6-8 weeks | Min Length: any Min Width: any Max Length: none Max Width: 15 ft before seam | New Zealand wool, blended wool, banana silk, viscose,bamboo silk, polyester. | Cut pile and ADA Compliance |

| Machine Made | 4-12 weeks | Min Length: any Min Width: any Max Length: any Max Width: 15 ft | Matte nylon, luster nylon, Polyester and Polypropylene. | ADA Compliant, cut pile, cut/loop pile optional |

| Flat Weave | 6-8 weeks | Min Length: any Min Width: any Max Length: any Max Width: any | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, polyester and polypropylene. | ADA Compliant |

Blended Wool

There are dozens of techniques for blending colors when working with rug fibers, including using dyeing techniques such as double-dye or abrash, or using weaving techniques to create salt-and-pepper, gradient, or interwoven blends of colors. These techniques are unique innovations developed over the lengthy history of hand-made rugs.

Blending colors using abrash or double dye requires specific knowledge of the nature of the fiber and of the dye. It is an art form that requires experience to perfect. Using dyeing techniques to blend different shades results in an organic, fluid interplay of colors.

Using different weaving techniques to blend colors, like gradient or “salt-and-pepper” rely on placing different complementary colors into a region of a rug to create a pleasing, controlled variation of colors.

These are perfect for creating consistent patterns and color blends in your rug. Because there are so many weaving and dyeing techniques, our team of expert designers frequently works with the client to best translate their concept to reality. This includes providing input on the best color blending techniques for their project and design vision.

Blending with wool

There is no concrete definition for “blended wool”- some manufacturers will use that to refer to a mix of wool from different origins. Others will use it to refer to the blending of wool with other fibers, which is a common practice in the hospitality industry. Our area rugs are always made using single-origin, high-quality New Zealand wool and we never blend with lower-quality Indian or Himilayan wools. When we talk about “blending” with wool, we refer to the addition of fibers such as nylon, silk, tencel, jute, and other synthetic fibers to imbue the rug with additional textural and visual characteristics.

Nylon

Blending wool with nylon is one of the best-kept secrets of the rug industry. Modernrugs.com Hospitality uses different ratios of woolto-nylon to create different grades of carpet suited for high-traffic spaces. Nylon adds stain-resilience and construction strength, making it a popular blending option for high-traffic hospitality and commercial spaces.

Silk

Blending wool with silk adds a lustrous sheen to the rug and creates a pleasing organic variation. A rug with silk content will interact with the light in pleasing ways, highlighting certain areas of the rug, or creating a uniform luster. This can be a fantastic option to create a stunning visual effect in a rug.

With a multitude of material blending options, our design team will gladly assist in making recommendations for the best materials to meet your aesthetic and performance requirements

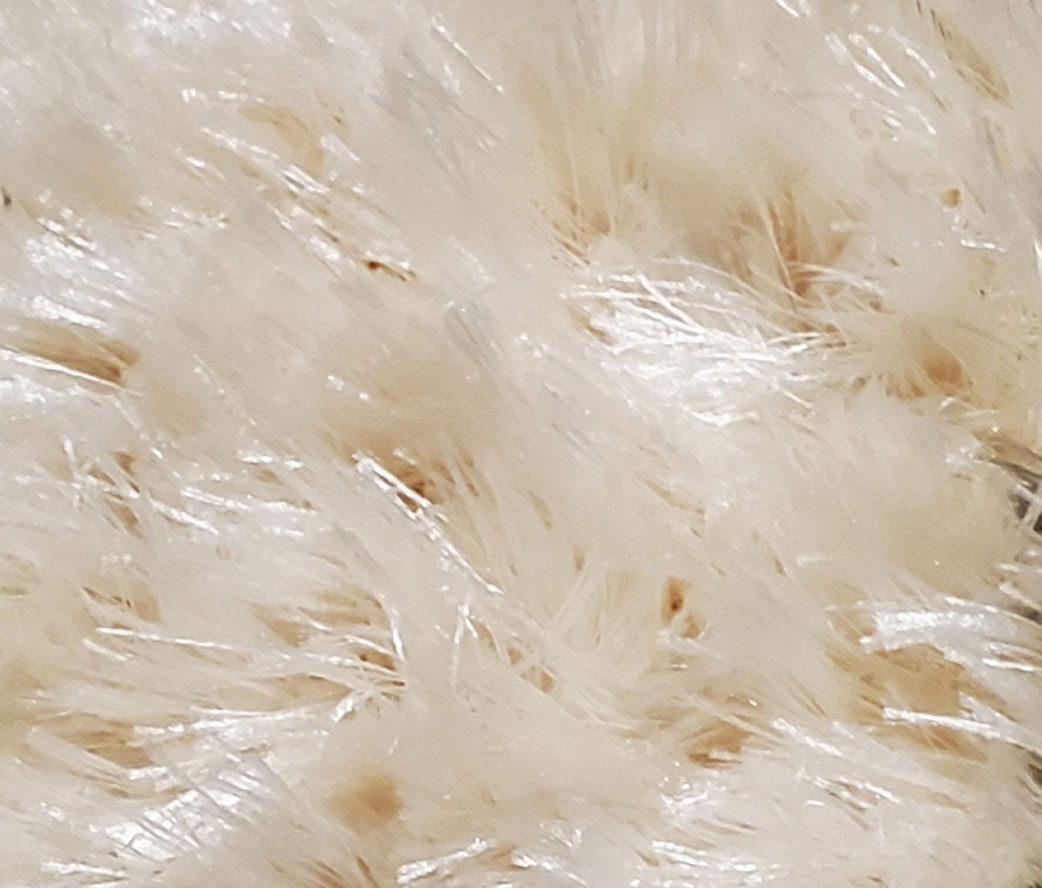

New Zealand Wool

Well known as the whitest and purest wool in the world, this particular wool holds dye extremely well and enhances any color dye because of its bright white base. Because the sheep are raised in high altitudes and less arid climates, they produce a higher level of lanolin (a natural oil secretion) in their fibers which makes the wool stronger, more insulating and more resistant to soiling. All of our custom rugs are made with hand spun New Zealand wool, unless otherwise specified.

Banana silk

Viscose, also known as "Art Silk" or "Banana Silk" is considered a synthetic material, although the fiber is made from the natural cellulose of cotton and wood pulp. Because of its cellulosic properties, viscose behaves like cotton, yet shines like silk. Because of this, viscose is an economical alternative to silk that is perfect for residential use. Because this fiber is not intended for high traffic areas or repeated wet-cleanings, it is not recommended for commercial use or rug designs featuring more than 50% silk.

Bamboo silk

Bamboo silk is a superior type of viscose because it is made from bamboo fiber rather than wool or other materials. As a fibre, Bamboo is growing in popularity due to it being a wonderful renewable resource. Bamboo is easy to grow, reaching up to 23 meters a year, and does not require replanting, making it an ideal rug fibre from the perspective of sustainability.

While these exceptionally attractive decorative carpets are not made to last for generations and to gracefully endure heavy traffic as are most of our other products, their unique sheen and texture are alluring and allow us to create them at significantly lower price point than if they were made with real silk. We recommend Bamboo Silk rugs by cleaned by a professional.

Bamboo and other plant based silks (banana silk, viscose, art silk) are not recommended for high traffic areas, but are a wonderfully affordable solution for budget-conscious projects with low traffic environments.

Loop

HIGH LOW

HAND TUFTED

HAND KNOTTED FINE WEAVE

SHAG ULTRA FINE

DOUBLE DYE

SALT & PEPPER

ABRASH

NATURAL FIBER BRAIDED

NATURAL FIBERS FLAT WEAVE

OUTDOOR FLAT WEAVE

COWHIDE