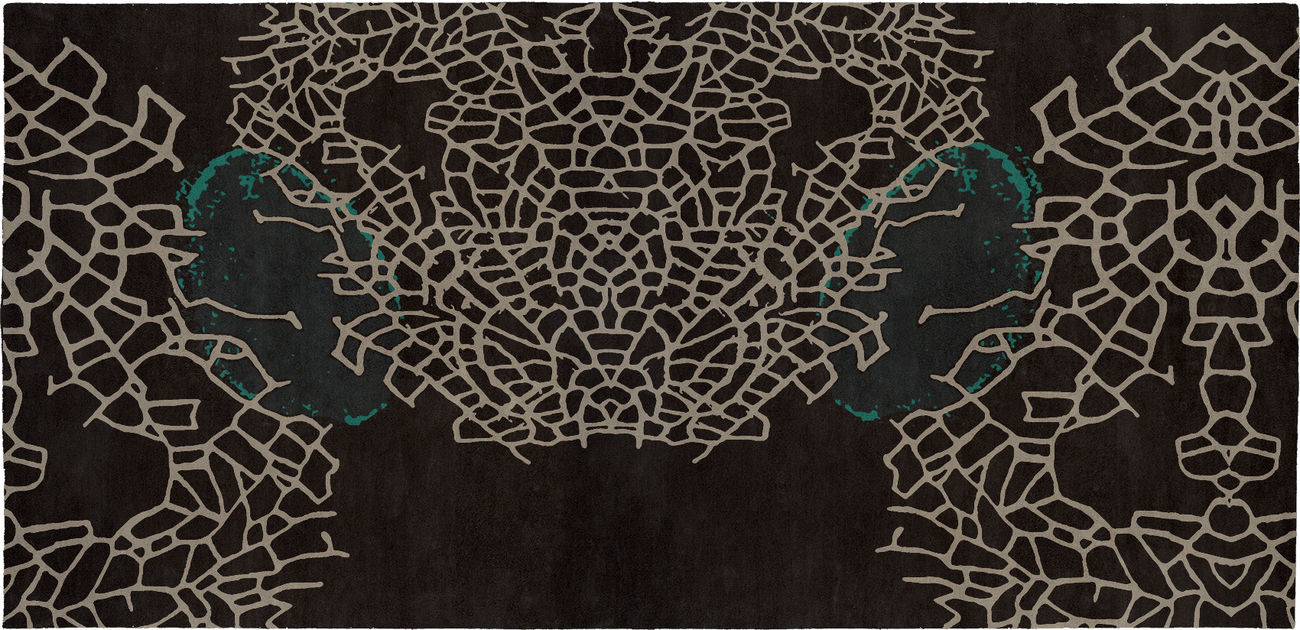

Fully Customizable: Shape, Size, color, material, and weave.

The product pictured above comes standard in a Ultra Dense Hand Tufted Hospitality construction. However, we have a multitude of customization options available for every design- including different constructions, material modifications, color substitutions and tailored shapes and dimensions. Check out the other construction options in the drop-down list below to learn more about the available customizations. We'll expertly outfit you with the perfect product for every project.

These designs are made-to-order and samples require a 2-4 week lead time. Please contact us to customize the sample to suit your specific project needs. In-stock samples are first come first served.

| Category: | Commercial Rugs |

| Collection: | Public Spaces |

| Made In: | India |

| Material: | 100% New Zealand Wool |

| Featured Quality: | Ultra Dense Hand Tufted Hospitality |

Also Available In these Qualities

Hand knotted rugs reflect the oldest and most traditional process of rug-making. Created with tremendous patience and pride, these magnificent and functional rugs are an investment that actually appreciates in value because of how beautifully they age. These rugs are created by tying knots of wool yarn onto a loom - a simple yet incredibly tedious process. The more knots per square inch, the higher the quality and price. Density ranges anywhere from 25-1000 knots per square inch. So, to give you an idea of how laborious construction is - it takes a skilled weaver about 10 seconds to tie each knot, meaning a 9'x12' rug, using 150 knots per square inch, would take 6,480 hours to complete. However, knotted rugs are usually woven by two or three to reduce the lead time. We offer the following hand knotted qualities: : 80 knots per inch and 5/8" pile height 100 knots per inchand 3/8" pile height 110 knots per inch and 3/16" pile height

| USE | Commecial medium to high traffic |

|---|---|

| ORIGIN | India, Nepal, China, Turkey |

| PRODUCTION TIME | 12-14 weeks EXPEDITED 10 weeks |

| SIZE LIMITATION | None |

| COLOR LIMITATION | PantoneTM, Sherwin Williams, ARS 600, ARS 1200, ARS 1600, Custom dye to match. |

| SHAPE LIMITATION | None |

| MINIMUM QUANTITY | None |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| DENSITY | 40-300 Knots Per Square Inch |

| BACKING | None |

| MATERIALS | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk. Metallic thread, Fiber Optics, |

| DYE OPTIONS | Solid, abrash, double dye, salt and pepper. |

| FINISHING OPTIONS | Cut pile, cut and loop, high-low, carving, oddshape, ADA Compliance |

| APPLICATIONS | Lobbies, hotel rooms, presidential suites, high end residential. and boutique hotels, boardrooms. |

1/2" - 2" Inch

Hand tufted rugs are a great example of how technological advancements have made luxury more accessible. Because hand tufted rugs are created with the help of a mechanized hand tool, the process is much quicker and less labor intensive than hand knotting. Therefore, the lead time is shortened and the price is more affordable than a hand knotted rug. A hand tufted rug can always be distinguished from a hand knotted rug because of the cloth backing glued to the underside.

| USE | Medium Traffic( Classic Commercial ), High Traffic( in Ultra dense) |

|---|---|

| ORIGIN | India, China, Thailand |

| PRODUCTION TIME | 6-8 weeks EXPEDITED 5 weeks |

| SIZE LIMITATION | None |

| COLOR LIMITATION | PantoneTM, Sherwin Williams, ARS 600, ARS 1200, ARS 1600, Custom dye to match. |

| SHAPE LIMITATION | None |

| MINIMUM QUANTITY | None |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| PILE HEIGHT | 0.625 in |

| BACKING | Canvas |

| MATERIALS | Wool, silk, nylon, viscose, banana silk, tencel, bamboo silk., metallic thread, fiber optics, |

| DYE OPTIONS | Solid, abrash, double dye, salt and pepper. |

| FINISHING OPTIONS | Cut pile, cut and loop, high-low, carving, oddshape, ADA Compliance |

| APPLICATIONS | Lobbies, hotel rooms, presidential suites, high end residential. and boutique hotels, boardrooms. |

The Quick Ship collection brings creativity to life in precise lines, photo realistic detail, vivid color and smooth gradients - all translated in 76 dpi high-definition, dye injection technology delivering five times the clarity of existing carpet color processing machines. Quick Ship offers high-speed production without compromising color, detail, precision and performance.

| USE | High Traffic |

|---|---|

| ORIGIN | USA or CHINA |

| PRODUCTION TIME | 4 weeks |

| SIZE LIMITATION | 12' Width |

| MINIMUM QUANTITY | 250 yards - ( order may have multiple designs if totaling 250 yards ) |

| MAXIMUM QUANTITY | Any |

| MODEL ROOM/SAMPLE | 3 weeks |

| SHIPPING METHODS | Air freight 7-10 days; ocean freight 21-45 days |

| PILE HEIGHT | 0.25 in |

| BACKING | Woven Polypropylene |

| PILE MATERIAL | Nylon |

| DYE METHOD | Injected |

| FINISHING OPTIONS | Cut Pile, Textured |

| APPLICATIONS | Lobbies, Guest Rooms, Residential, Suites, Workplaces, Public Areas, Hallways, Yachts, Airplanes, Wall-to-Wall |

| Material | Nylon |

|---|---|

| Primary Backing | Woven Polypropylene |

| Secondary Backing | Latex Backing |

| Surface Texture | Cut & Loop Tip Shear |

| Dye Method | 100% Solution Dyed |

| Pile Height | 0.272" Custom Tip Shear |

| Widths | 12'0" / 13'6" / 15'0" |

| Gauge | Tufted 1/10th |

| Stitch Count | 11 spi |

| Pile Weight | 36 oz/sqyd |

| Total Weight | 79.4 oz/sqyd |

| Soil Resistance | Commercial Anti-Soil Protection |

| Flammability | DOC FF 1-70 (pill test); ASTM E648: Class 1; ASTM E662: Less than 450 |

| Warranty | Yes |

Axminster, a traditional woven carpet developed over 250 years ago for royal residences, is now used almost universally in the hotels and other commercial locations due to its crispy clear patterns and long-term durability. As a broadloom carpet, Axminster can be manufactured in several different qualities. This means that Axminster can work in both light-commercial and heavy-commercial situations.

| Aspect | Cut pile |

|---|---|

| Dye Method | Hand Dyed |

| Width | 13.1 ft. |

| Primary Backing | Polypropylene weft / Polyester-based warp |

| Secondary Backing | Copolymer |

| Pile Fiber Composition | 80% wool - 20% polyamide |

| Total Thickness | 0.4 in. |

| Effective Pile Thickness | 0.28 in. |

| Total Mass | 56.1 oz/sqyd |

| Total Pile Mass | 44.0 oz/sqyd |

| Effective Pile Mass | 30.0 oz/sqyd |

| Pile Density | 0.0052 lb/in2 |

| Number of Tufts | 81520 tufts/sqyd |

| Code Compliance | ISO 6356 (stroll test); ISO 10966 (Vertical & Horizontal Resistance) |

| Use Classification | EN 1307 (33 Commercial - Heavy Use) |

| Luxury Rating | EN 1307 (LC 5) |

| Impact Sound Reduction | 32 dB |

| Noise Reduction | 0.20 aw |

| Thermal Resistance | 0.159 m2 K/W |

| Flammability | Bfl -s1 (glued tested) |

| Prodis - GUT | 23316 |